The heartbeat of Aston Martin’s sports car range just got that little bit faster with the introduction of the new Vantage Roadster. Joining the Vantage Coupe, which was launched in 2018, this convertible model amplifies the emotional appeal of a model renowned for delivering a compelling blend of potent performance, outstanding dynamics, and everyday usability.

Read More2022 Fisker Ocean All-Electric Luxury SUV Exclusive Driving Footage and New Specifications Revealed

The world’s most sustainable vehicle can be seen in action, reflecting the production-ready platform’s maturity, reliability, and performance. The footage, by Fisker Inc., was directed by cinematographer Phil Arntz in association with SP Films

Read MoreCustom Rumble: voting is open for the best-looking Ducati Scrambler custom bike

The Ducati Scrambler based specials created by participants in the Custom Rumble, the contest that every two years rewards the best-looking customized Ducati Scrambler, are ready to be voted on Scramblerducati.com.

Read MoreAston Martin V12 Speedster

Aston Martin V12 Speedster A Puristic Limited Edition for the most Demanding Drivers

Created by luxury British marque’s bespoke customization service ‘Q by Aston Martin’, the Aston Martin V12 Speedster is a truly visceral driver’s car that draws inspiration from both the brand’s rich racing history and aeronautical design.

Read MoreVW Customer feedback makes the Polo GTI R5 even better.

Fine-tuning for the car with the winning touch: Volkswagen Motorsport is optimizing the Polo GTI R5, based on the experiences of customer teams.

Read MoreHertz Awards Custom 2020 Hertz-Hendrick Motorsports Camaro

Hertz and Hendricks Motorsports Create a Special Experience for Five Finalists and One Big Winner of the Hertz Ultimate Ride Sweepstakes

ESTERO, Fla., March 5, 2020 Last week Hertz announced Phillip Abma as the winner of the Ultimate Ride Sweepstakes in celebration of its limited-edition custom 2020 Hertz-Hendrick Motorsports Camaro ZL1 and SS models. The custom Camaros debuted last fall and are available for rent this Spring.

Phillip Abma as the winner of the Ultimate Ride Sweepstakes and with Race Driver William Byron

"Last week's event helps us celebrate our rich car culture history providing the right vehicle to meet customer needs, whenever and wherever they need it," said Hertz Senior Vice President Jayesh Patel. "We're delighted to share the powerful and exhilarating experience of these vehicles with our customers and congratulate Phillip Abma on winning this ultimate ride."

The Hertz Ultimate Ride Sweepstakes brought five finalists to Charlotte, NC for a special experience and the chance to drive home with the Hertz-Hendrick Motorsports Camaro SS. The finalists, Gina Golshani of Oklahoma, Dion Hansen of California, Steven Ipson of Ohio, Tamra Mays of Texas and Phillip Abma of Florida were whisked away to Charlotte, NC for a two-night hotel stay with first-class airfare for themselves and a guest. To further enhance the experience, they received a three-day Hertz Premium/Adrenaline collection car rental, $1,000 cash and a heart-pumping track day at Charlotte Motor Speedway with the Hendrick Motorsports Team. William Byron, driver of the No. 24 Hertz Chevrolet ZL1 LE1 turned laps with each finalist in a Hertz branded two-seater race car before a tour of the Hendrick Motorsports facilities. The five winners were then given specially coded key chains. The person with the key that started the 2020 Hertz-Hendrick Motorsports Camaro SS won the grand prize of the Ultimate Ride and $15,000 cash.

Abma was excited to take his two children, Leilani (12) and Ethan (8), to a city they had never been to but never expected to win the grand prize, which is valued at more than $72,000.

"Winning the car is something I cannot put into words," said Abma. "I was not expecting the car to start when I hit the button and I was beyond surprised when it did."

The first thing he plans to do is show the car to his family, who are located in Miami, FL. He has always wanted a Camaro, and now he is the proud owner of a custom Hertz-Hendrick Motorsports Camaro SS.

"The experience was incredibly awesome," said Abma. "To be in a race car with a professional driver at insane speeds was a once in a lifetime experience. Riding with William Byron was awesome. I used to be 'that guy' who used to think it was just driving and easy. Boy was I ever wrong. It is beyond comprehension how they can deal with the forces exerted for over 200 laps."

Fashioned in the signature Hertz yellow and black color scheme and full performance upgrades outfitted by NASCAR's most successful team, Hendrick Motorsports Equipped with 480 horsepower and a 6.2L V8 engine, the 2020 Hertz-Hendrick Motorsports Camaro SS is optimized with 20-inch satin black wheels; a Performance Upgrade Package inclusive of a Chevrolet Cold Air Intake and Chevrolet Cat-back Dual Exhaust Upgrade System; custom exterior graphics package; strut tower bar with Hendrick Motorsports branding; custom Hertz lighted door sill plates; embroidered headrests with the No. 24 team logo and William Byron's signature; Hertz fender badges; and a Hertz-Hendrick Motorsports plaque denoting the individual numbering of the 200 custom Camaros.

The Hertz-Hendrick Motorsports Camaros are available at select Hertz airport locations, including Charlotte, N.C., Dallas, Texas, Ft. Lauderdale, Fla., Ft. Myers, Fla., Houston, Texas, Las Vegas, Nev., Los Angeles, Calif., Miami, Fla., Nashville, Tenn., Orlando, Fla., Phoenix, Ariz., San Diego, Calif., San Francisco, Calif., Tampa, Fla. And West Palm Beach, Fla.

FCA to Invest $400 Million to Convert Kokomo, Ind., Plant

KOKOMO, Ind., March 5, 2020

FCA North America COO makes announcement joined by Indiana Governor

Indiana Transmission Plant II in Kokomo to be transformed into engine plant

Revamped facility to retain about 1,000 jobs and add nearly 200 more, bringing total FCA employment in Indiana to more than 8,300

GMET4, part of FCA's Global Medium Engine family, provides outstanding fuel economy and low emissions

Engine to play an important role in electric engine offerings

U.S. production of the GMET4 relocated from Italy

Facility to be renamed Kokomo Engine Plant; production to start in Q2 2021

FCA has invested more than $2 billion in Indiana and more than $14 billion in the U.S., while adding more than 30,000 new jobs, since 2009

FCA announced that it will invest $400 million to repurpose an idled transmission plant in Kokomo, Ind., to build the GMET4 engine – the Company's 2.0-liter Global Medium Engine inline four-cylinder turbo that is currently offered on the Jeep® Wrangler and Jeep Cherokee. With this investment, 1,000 Indiana jobs will be retained with nearly 200 new jobs added to support production, bringing total employment in the state to more than 8,300.

{L} Indiana Governor Eric Holcomb & FCA NA COO Mark Stewart {R}

FCA North America Chief Operating Officer Mark Stewart, along with Indiana Governor Eric Holcomb, Kokomo Mayor Tyler Moore, UAW Vice President and Director of the FCA Department Cindy Estrada and UAW Region 2B Director Rich Rankin, joined other local officials and guests to celebrate the news at an event at the plant, which will be renamed Kokomo Engine Plant.

In his remarks, Stewart talked about the importance of this engine to the Company's future powertrain strategy.

"The GMET4 will be a very important engine for us as we look to deliver on the promises we made as part of our five-year plan in 2018," Stewart said. "While the 2.0-liter is a current engine option on the Jeep Wrangler and Cherokee models, a significant number of new technologies can be applied to this engine, making it relevant for the future. It will play an important role in our plans to offer electric engine options across 30 nameplates that FCA will bring to markets around the world by 2022."

The new facility will be the source of all U.S. production for the engine currently built in Termoli, Italy. Production is expected to begin in Q2 2021.

Stewart acknowledged the support of the State of Indiana, the City of Kokomo and the UAW for working with the Company to finalize its investment plans.

"I'd like to add my appreciation to both Governor Holcomb and Mayor Moore for seeing the opportunities that exist with this investment and helping give this facility new life," Stewart said. "I also want to thank Cindy Estrada and Rich Rankin, as well as the rest of the UAW leadership, for working with us to preserve and add jobs. Their support will be critical to building a quality engine for our customers."

For more than eight decades, FCA has built transmissions in Indiana, more than 90 million since record-keeping began in 1974. Since 2009, the Company has invested nearly $2 billion in its four area plants to produce the eight- and nine-speed transmissions, some of the most fuel-efficient transmissions on the market. When production of the GMET4 launches, it will mark the first time in the Company's history that it has built engines in the state.

But, according to Stewart, the decision to invest in Indiana and transform the plant into the Kokomo Engine Plant came down to the level of commitment shown by the women and men who work in the region.

"As engine technology continues to change, our focus must continue to be on our most valuable asset – our people," Stewart said. "This engine program will bring new job opportunities for our current workforce, as well as the manufacturing workforce of the future. Our employees – some of whom are second-, third- or even fourth-generation FCA employees – have always demonstrated a passion to help deliver great products for our customers."

In total, FCA has committed to invest more than $14 billion in its U.S. manufacturing operations, creating nearly 30,000 new jobs since June 2009.

GMET4, part of FCA's Global Medium Engine family

GMET4 Engine

The 2.0-liter turbocharged I-4 engine is part of FCA's Global Medium Engine family. Identified as the GMET4, this high-tech, direct-injection engine uses a twin-scroll, low-inertia turbocharger mounted directly to the cylinder head, along with a dedicated cooling circuit for the turbocharger, intake air and throttle body for exceptional responsiveness, performance, and fuel efficiency. The engine is fitted with double overhead camshafts, dual independent camshaft timing and cooled exhaust gas recirculation. Direct injection delivers fuel into the cylinder and, coupled with turbocharging, enables more efficient combustion, reduced emissions and increased performance. The foundation of the engine is a low-pressure sand cast-aluminum block with cast-in iron cylinder liners and a cast aluminum alloy cylinder head.

When equipped with the GMET4, the Jeep Cherokee can deliver over 30 mpg highway and provide outstanding off-road performance, while the Jeep Wrangler can deliver a rating of 24 mpg highway.

FCA in Indiana

Construction of Indiana Transmission Plant II (ITPII), which will be renamed Kokomo Engine Plant, began in 2002 and launched production of five-speed transmissions in November 2003. The plant also produced components for eight-speed transmissions. ITPII built its last five-speed transmission in August 2018 and was idled in the fall of 2019.

FCA currently operates three transmission plants and one casting plant in Indiana. The portfolio of transmissions includes four-, six-, eight- and nine-speed transmissions, as well as the SiEVT transmission for the Chrysler Pacifica plug-in hybrid electric minivan, built at the Windsor Assembly Plant in Ontario, Canada. The casting plant produces aluminum parts for automotive components, transmission and transaxle cases, and engine block castings.

Maserati starts testing the prototype of the new MC20

Modena, 5 March 2020. Following the "mule" tests, the first full prototype of the new Maserati MC20 super sports car has emerged from the Maserati Innovation Lab in Modena.

Maserati has 100% Italian DNA and is in continuous movement: the Brand has identified and selected a series of iconic locations in Italy that effectively convey the “Masters of Italian Audacity” global statement, of which the new MC20 is the first and ultimate expression.

The prototype has been photographed at night in Piazza degli Affari in Milan, below Maurizio Cattelan's sculpture L.O.V.E., a symbol of Italian audacity in international contemporary art.

Now, this marks the start of a period of road and track tests, in various conditions of use, to acquire vital data for the preparation of the car's final setup.

During the next few days, the prototype will visit other locations symbolic of Italian audacity, before returning to Modena.

Maserati: Masters of Italian Audacity

@MikeBrewer is back in the UK with his favorite classic car!

.@MikeBrewer is back in the UK with his favorite classic car! Stream a new episode of Mike Brewer’s World of Cars NOW on the @MotorTrendOnDemand App! 🚗💂https://t.co/IJena9NxNm#MikeBrewersWorldofCars #MotorTrend #Mini #Europe pic.twitter.com/TDAzqkVhdj

— MotorTrend TV (@MotorTrendTV) March 10, 2020

Czinger 21C ready for its London, UK public unveiling on 10 March, in Geneva with derig in the background

Czinger announces worldwide reveal plans for revolutionary 21C hypercar

Czinger publishes finished Cancelled Geneva International Motor Show 2020 stand images and announces future worldwide debut plans

The global public debut of groundbreaking Czinger 21C hypercar and presentation of Czinger as a brand, its mission, and future will take place on 10 March 2020

Presented by CEO and Founder Kevin Czinger live from 18:30 London local time (GMT) an exclusive London, UK location

Live on czinger.com/livestream and Czinger’s social media channels

Having finished its stand and flown the team to Geneva, Czinger Vehicles has announced that the show will go on – in London, UK – and released images of its completed Geneva International Motor Show 2020 booth.

Czinger will globally launch as a brand, unveil its 21C hypercar and explain its current mission and future plans on 10 March at an exclusive London, UK location from 18:30 GMT, which will be streamed online as well.

Displaying its innovative spirit and pathbreaking approach as a brand, Czinger completed its Geneva International Motor Show stand build and lifted the covers off its two revolutionary 21C hypercars with a twist – mounting bikes and surfboards on top in a nod to the brand’s Californian heritage.

Limited to just 80 cars, the 21C is built for the 21st century, with an innovative approach to total vehicle design, using revolutionary manufacturing technologies to achieve dominating performance and iconic design.

Placing the driver and passenger in the middle of the car in a jetfighter-style layout, the 21C is capable of 0-62 mph in 1.9 seconds and a quarter-mile time of 8.1 seconds. Czinger has utilized its own revolutionary technologies to create a 1250hp drivetrain and computational manufacturing methods to keep the dry weight under 1200kg, for that all-important 1:1 power-to-weight ratio.

Renault F1 Team officially launches its 2020 campaign

Renault F1 Team today outlined its plans for the upcoming 2020 FIA Formula 1 World Championship season.

Drivers Daniel Ricciardo and Esteban Ocon were presented publicly in team colors for the first time.

The event took place at Groupe Renault’s flagship store, L’Atelier Renault, on the Champs-Elysees, Paris, underlining the ongoing support and commitment of the Groupe to Renault Sport Racing.

New Chassis Technical Director Pat Fry was also present, alongside the top management of the team, Cyril Abiteboul, Alain Prost, Marcin Budkowski and Rémi Taffin.

Formula 2 Rookie of the Year Guanyu Zhou steps up his role to Test Driver.

Renault F1 Team highlighted its valued support from premium partners: BP Castrol, MAPFRE, DuPont, INFINITI, Microsoft, EURODATACAR, Bell&Ross, le coq sportif, and RCI Banque as well as its portfolio of beneficial technical partners and suppliers.

Renault F1 Team officially kicked off its 2020 campaign today with its season opener event on the Champs-Elysees, Paris, at Groupe Renault’s flagship store, L’Atelier Renault.

Dynamic driver duo Daniel Ricciardo and Esteban Ocon were unveiled for the first time in team colors to attending media and partners, along with newly-arrived Chassis Technical Director Pat Fry.

Glimpses of the 2020 challenger, the Renault R.S.20 in its pre-season testing livery, were teased to the watching audience, which will be fully revealed, along with its power unit the E-Tech 20, at winter testing in Barcelona next week.

Following on from January’s series of announcements, the 2020 Renault Sport Academy Drivers were also in attendance at the event as they gear up for an exciting year across FIA Formula 2, FIA Formula 3 and the Formula Renault Eurocup.

Renault Sport Racing Jérôme Stoll

President of Renault Sport Racing Jérôme Stoll commented on 2020 being a crucial year in Renault’s journey in the sport: “This year, Renault will continue its very proud and long-standing history in Formula 1 into a new decade, our sixth consecutive in the sport. 2020 is a significant year in a number of ways. We aim to recapture the positive momentum from our first three years since returning to Formula 1 while preparing for next season, which will represent a new cycle for all teams. Having completed our initial construction phase, we are more determined than ever to be ready to attack and take advantage of the 2021 technical changes. I have every faith in the teams across Enstone and Viry to challenge once more for fourth in the Constructors’ Championship this year, plus ensure the coming era is anticipated successfully for both the team and Renault brand.”

The team is reaching the climax of its consolidation phase of the Formula 1 programme. It has invested healthily in personnel and state of the art technology across its chassis base in Enstone, United Kingdom, and engine headquarters in Viry-Châtillon, France, to aid its plan of, once again, claiming Formula 1 world championship titles.

Team Principal Cyril Abiteboul Renault Sport Racing

Team Principal Cyril Abiteboul highlighted the team’s ambitions for the season. “Taking back fourth position in the Constructors’ Championship remains the objective over a season that will be more hotly-contested than ever.

“For the coming season, we must respect the three priorities identified during the off-season: reliability from the get-go; ensure a high level of development very early in the season and have a good conversion rate on track. However, we also need to regain confidence and reinforce team spirit to get the best from everyone, and to maximise our chances each race weekend during this unprecedented long and challenging season.

“2020 is also a pivotal year that marks the end of one cycle and the preparatory phase of another. This year must see us setting the best possible course for the major regulation changes of 2021. The organisational changes made in the second half of 2019 are with this firmly in mind.”

Daniel Ricciardo

Daniel Ricciardo enters his second season in black and yellow and revealed his motivation to succeed on track this year. “I’m looking forward to blending into the team better on the back of having a full season behind us - so things are going to be easier in that sense. I learnt a lot about myself and obviously a lot about the team. One of the most important learnings for me was that it’s not just about having the smartest guy in the Formula 1 paddock - you need every individual across the team getting the most out of themselves. With the people I work closest with it’s about trying to find a way they work best, trying to help them be their best selves, and then also figuring out where I can perform the best on the day. I’ve enjoyed this experience so far and building something with Renault.”

Esteban Ocon

Esteban Ocon is raring to jump back in the race seat as he marks his return to the team, which gifted him his early taste in Formula 1 as a teenager. “It’s very exciting and I can’t wait to test the new car in Barcelona. We’ve had a lot of time to prepare, and I’m feeling ready for the challenge. I’m really looking forward to racing again – back where I want to be – after waiting for a year. There are a lot of new items on this year’s car and the guys have been working hard to find some additional performance. It’s all about details in Formula 1 and I’ve seen quite a lot of details on the Renault R.S.20. It’s exciting to see the design but the next thing you want is to be behind the wheel and feeling what it’s like.”

Guanyu Zhou

Guanyu Zhou takes on a new role this year as he is promoted to Test Driver. The Formula 2 Rookie of 2019 will have increased responsibility in contributing to the development of the 2020 car. “I’m looking forward to becoming the team’s Test Driver,” commented Zhou. “It’s another step up from being Development Driver in 2019. This year I have an even better opportunity, meaning working harder than before, getting as much information as possible for driving a Formula 1 car and, at the same time, improving the areas the team needs to work on to help them get better in the future.”

With a sense of positive energy demonstrated by the drivers and the strengthening ties between Enstone and Viry, 2020 looks to be an exciting season on and off track.

How the Brabham BT62 Set a Bathurst Lap Record

The first weekend in February 2020 saw the running of the Bathurst 12-hour. The same weekend in 2019 saw the Brabham BT62 make headlines, setting the fastest time ever for a closed-wheel vehicle around Australia’s most famous circuit.

Just how fast was that lap? And how did we do it?

V8 Supercars are Australia’s most popular racing class. It’s the series that carries the torch and continues the mystique of Bathurst as Australia’s most challenging, and most famous, racing circuit. Its champions are household names in Australia – Jane, Firth, Brock, Moffat, Johnson, Bowe, Richards, Brabham, Perkins, Skaife, Lowndes and Whincup.

The fastest-ever lap around Bathurst in a V8 Supercar was last year’s Bathurst 1000 pole position qualifier, Scott McLaughlin, at 2:03.378.

The fastest-ever GT3 lap at Bathurst was driven in 2016, in a McLaren 650S GT3 – a time 2:01.567. A de-restricted GT3 car (an Audi R8) has also gone around the track in a time of 1:59.321.

On 2 February 2019, the Brabham BT62 surpassed them all, setting a lap time of 1:58.679 – shaving 2.9 seconds from the GT3 lap record and an astounding 4.7 seconds from Australia’s fastest ever V8 Supercar lap. What makes the record all the more remarkable is that it was broken after only 12 exhibition laps without any real set up time.

How did the BT62 do it?

The simple answer is an outstanding driver and even more outstanding vehicle dynamics.

Luke Youlden is no stranger to Bathurst. He’s lapped the Mount Panorama circuit thousands of times, completing the gruelling Bathurst 1000 race multiple times over his professional career, tasting victory in 2017.

He’d never been in a car this dynamic, however, with blazing speed up Mountain Straight, amazing handling through the twisting top section of the circuit and enough power to seemingly shorten Conrod Straight and The Chase before crossing the start/finish line.

To put this lap in perspective:

The BT62 covered more than an Olympic swimming pool per second, averaging 188.5 km/h around the 6.213 km circuit.

At the speeds it was travelling – and given the BT62’s low weight and amazing downforce capabilities (up to 1600kg at top speed) – the car could have driven around 14% of the lap upside down.

The car pulled maximum loads of 2.89 g in the corners, 1.24 g under acceleration and a massive 3.51 g under brakes. That maximum braking instance involved 80kg of leg pressure applied to the pedal and resulted in the BT62’s carbon/carbon brakes heating to 675C degrees, a comfortable operating window for brakes used in F1 cars.

The power to reduce the 3kms worth of straights comes from the Brabham 5.4 litre, naturally aspirated V8 engine producing 700hp at 7400 rpm. Combine this with a 6-speed Holinger racing gearbox weighing just 63 kilos with a super-fast gear change, and you have a hypercar capable of rapid acceleration; a car that gets faster, sooner, maximising your time at top speed on the straights.

Power is nothing without control, however, and the BT62’s superior chassis dynamics and outstanding aerodynamics proved invaluable over the twisting top section of the mountain circuit.

The chassis itself is a masterpiece of design and construction. Manufactured from lightweight, high-tensile steel it provides unrivalled torsional rigidity, allowing Brabham’s engineers to concentrate on tuning the suspension to deal with the track rather than compensating for compromised chassis performance. The chassis features adjustable anti-roll bars, full camber adjustment and industry-leading, 4-way adjustable, racing dampers.

Working with the chassis to keep the car glued to the road is an aerodynamics package producing up to 1600kg of downforce at top speed. The BT62’s sculpted body is designed to manage airflow over the whole body as a continuous surface. This optimises aero performance by keeping the high-pressure air working on the upper surfaces and low-pressure air working on the underfloor. Any low-pressure wake is kept away from the critical aero surfaces and air intakes, ensuring maximum downforce and adequate cooling flow to the powertrain.

The Brabham BT62 is a tour de force of technical know-how, producing performances that rank second only to the top echelons of open wheel racing.

Born from champions, the Brabham BT62 delivers world-beating performance for the champions of tomorrow.

As for Mount Panorama, the BT62 holds the record but still has unfinished business – an even quicker time beckons.

Preview of the all-electric Audi S models – The signature S model treatment is destined for the Audi e-tron and e-tron Sportback, which gain three electric motors, lightning quick quattro reflexes with electrical torque vectoring and 973Nm of torque for the most dynamic and agile driving experience yet.

Audi Presents New Drive Concept For E-TRON S Models

Drive concept with three electric motors as a worldwide first in the future mass production

New quattro generation with electric torque vectoring

370kW of power and 973Nm (717.6 lb-ft) of torque for a high level of dynamic handling and agility

Ingolstadt, March 04, 2020 – Audi is systematically moving forward with its e-offensive: The Audi e-tron and the Audi e-tron Sportback are becoming more agile, sharper and more dynamic as S models. The three electric motors, two of which are located on the rear axle, together provide 370 kW of boost power and 973 Nm (717.6 lb-ft) of torque. This allows the two purely electrically driven models to accelerate to 62mph in 4.5 seconds. The intelligent drive control raises vehicle safety, and dynamic handling in particular, to a new level: In addition to the electric all-wheel drive, there is the electric torque vectoring with active and fully variable torque distribution on the rear axle.

Dynamism 2.0: the driving experience

The driving experience of the two prototypes for the Audi e-tron S-models cannot fail to impress with its level of dynamism, agility and traction increased once more. In the S gear, both cars go from a standstill to 62mph in 4.5 seconds – almost seamlessly and nearly no noise – propulsion does not end until 130mph, limited electronically. Thanks to a powerful cooling system, the drive gives the full boost power of 370 kW and 973 Nm (717.6 lb-ft) of torque in reproducible form for eight seconds in each case. The nominal values in the D gear without boost are 320 kW and 808 Nm (596.0 lb-ft).

In terms of handling, the electric S models cannot fail to impress with their outstanding agility and traction: They can accelerate from a corner as skilfully as a sports car, their drive character is much more focused on the rear wheels and much more dynamically in nature. If the ESC stabilization control is set to “Sport” and the Audi drive select dynamic handling system is set to maximum performance with “Dynamic” mode, the drive layout facilitates a high level of transverse dynamics and, on request, controlled drifts as well. The driving behavior is predictable at all times and is characterized by an ultra-high level of safety and reliability.

The drive layout: three electric motors in the future mass production

The new Audi e-tron S models will be the first electric cars worldwide with three motors in mass production. Their drive layout is based on the concept with two different asynchronous motors (ASM); the e-tron product line was designed in modular form in line with this from the start.

The larger electric motor, which powers the rear axle in the Audi e-tron 55 models, has now been installed on the front axle in an adapted design and configured for 124 kW of power, or 150 kW during boost. The smaller electric motor now works in a modified form in the rear, together with a counterpart that is identical in design; together, they offer 196 kW of power, or 264 kW in the boost.

Innovation from the quattro pioneer: twin motor with electrical torque vectoring

The drive has been programmed for efficiency in everyday life; in normal driving mode, only the rear electric motors work. The front-drive is unpowered but switches itself on – with the driver barely noticing – if the driver needs more power. It also switches on predictively if the grip declines. It does so when friction values are low and during rapid cornering. The electric all-wheel drive is complemented by a further technological innovation in the form of electrical torque vectoring, which brings the advantages of the conventional sport differential into the electric era. Each one of the rear electric motors sends the drive forces directly to the wheel via a transmission; there is no longer a mechanical differential. Forty years after the launch of quattro technology, Audi is thus raising the principle of the four powered wheels to a completely new level of technology. The result: more agile driving and self-steering characteristics, and thus a higher cornering speed.

One further advantage is the traction. If, during acceleration, a rear-wheel comes into contact with a road surface with a low friction value, i.e. if the road surface is covered in black ice or has a loose subsurface, the torque can be distributed precisely and quickly between the two motors. The full torque is gradually distributed to the wheel with powerful traction, while the wheel with low traction continues moving with almost no torque.

The two prototypes of the e-tron S models drive on 20-inch alloy wheels in the 5-V-spoke S design as standard. Different wheels up to 22 inches in size are available on request. To achieve an S-typical transverse dynamism, the tire widths in the sizes 20 inches, 21 inches, and 22 inches have all been enlarged to 285 mm. Black brake calipers with a red S rhombus, with six pistons at the front in each case, grip the large brake discs (front diameter: 400 mm). A further standard feature is the progressive steering – its ratio becomes more and more direct, the further the driver turns the steering wheel. The front and rear axles have been created as a five-link design. Harmonization of the elastokinematics and of the dampers has also been optimized for the S models. In order to even further reduce the rolling movements during cornering, the stabilizers on both axles have been enlarged.

Up to 150 kW: peak power, even during charging

When the driver is on the road, the electric S models can be charged with up to 150 kW of direct current power (HPC), such as in the UK and European Ionity network. This means that charging from 5 to 80% only takes around half an hour. An important factor for this is the elaborate thermal management system with a standard heat pump, which cools and heats the battery, the interior and the electric motors with four circuits. In addition, the Audi models will also be able to charge with up to 11 kW of alternating current (AC).

The Audi e-tron Charging Service guarantees convenient access to more than 140,000 public charging points in 24 European countries on request – with nothing more than a charging card. In the first year, Audi e-tron customers benefit from a year’s subscription to the transit tariff, which also offers access to high power charging columns. In addition, all new e-tron and e-tron Sportback customers ordering between 1 January and 31 December 2020 can receive £150 credit on their accounts, which translates into approximately 1,000 miles of free electricity.

In addition, all e-tron models currently benefit from a free wall box offer applicable to new customer orders placed from 1 January 2020. The Pod Point Universal socket 7kW Solo wall box (RRP of £879) enables overnight charging of the e-tron three times faster than using a domestic wall socket, and Audi UK will cover the cost of installation once the OLEV EVHS grant has been applied*.

Optical statement: widening the wheel arches

The powerful and dynamic design of the e-tron S models features the progressive Audi design vocabulary, which emphasizes the strong contours of the wheels. Details such as the octagonal Singleframe, which is, for the most part, sealed and painted bright grey, move the design into the electric era. At the lower edge of LED headlights, four struts create the e-tron-specific signature in the daytime running lights. The S models’ leading role can be seen straight away. The front and rear bumpers are heavily contoured, while the diffuser insert runs almost the full width of the vehicle. The bumper is flanked by bigger and more expressive air curtains, which improve airflow. They extend below the headlights, thereby creating a dynamic appearance even from a distance. On both sides, the wheel arches are a 23 mm wider. Silver-colored elements – from the lip of the front bumper, the Singleframe and the door inserts right up to the diffuser – emphasize the vehicle’s features. Audi will paint larger detachable parts in a contrasting color on request.

Both S models are available, on request, with the digital Matrix LED headlights, a worldwide first in mass production. Their light is dispersed into small pixels and can be controlled with high precision, and this facilitates many new functions such as lane and orientation light. In narrow areas, for example, it shows the car’s position in the lane and thus helps the driver to remain in the center.

Progressive: the interior and equipment

The interior of the future e-tron S models has been kept in dark colors. A large arc connects the displays of the virtual external mirrors with the bonnet above the Audi virtual cockpit. The instrument panel is driver-oriented, the middle tunnel’s console rests on open sidewalls. The electrically adjustable Valcona leather sport seats and the gear selector lever feature a rhombus S embossing. The door sills and steering wheel feature S badges. On request, Audi can offer a supersport seat in leather with a rhombus pattern in black, rotor grey or Aras red, as well as an air-conditioned customized contour seat with perforated leather.

McLaren Extends Relationship with Intelligent Money British GT Championship for a 5th Season

A record 12 entries running with McLaren Customer Racing, doubling the number on the grid from 2019

720S GT3 and 570S GT4 to contest Silver and ProAm classes across both GT3 and GT4 championships

McLaren 720S returns as official Safety Car

McLaren Automotive will once again be represented on the highly-competitive Intelligent Money British GT grid, as it is confirmed that a total of 12 McLaren entries will contest the GT3 and GT4 championships during the 2020 season. This will be the strongest-ever showing for the British brand with eight examples of the 570S GT4 battling for GT4 honors, while an expanded grid of GT3 cars will see teams battling for both ProAm honors and, for the first time, the Silver class championship. The grid will also be led by McLaren for the fifth successive season as the 720S Safety Car returns to action.

The 720S Safety Car will manage and co-ordinate all on-track activities at each of the nine races, leading a record 34-car grid, with one-third made up of McLaren Customer Racing teams. This announcement further strengthens the relationship between McLaren Automotive and the SRO-run series which now enters a fifth year.

720S GT3 to challenge for ProAm and Silver titles

In the GT3 championship, Balfe Motorsport returns with the 720S GT3 for a second season and an unchanged ProAm line-up from 2019 of Shaun Balfe and McLaren Factory Driver Rob Bell. The pair are looking to pick up where they left off last season, having scored a race victory at the season finale at Donington Park to secure third in the championship.

Two new Customer Racing teams will also take to the British GT grid fielding the 720S GT3 for the first time in 2020. Championship regulars, and reigning GT3 Silver class champions, Optimum Motorsport confirmed a switch to McLaren over the winter and the Wakefield-based team will run with Australian driver pairing Nick Foster and Martin Berry, who are both new to the series. Completing the McLaren Customer Racing GT3 runners and riders is the newly-established 2 Seas Motorsport with a two-car entry both battling for Silver class honors. Angus Fender will share with McLaren GT4-race winner Dean MacDonald for one entry, while Championship debutant Isa Al-Khalifa has been confirmed in the second car. His driving partner is expected to be confirmed in the coming days.

Biggest ever McLaren presence on the GT4 grid

The GT4 class within the Intelligent Money British GT championship continues to grow in stature, and the grid gains strength each year with 2020 being no different. This season sees no less than eight examples of the 570S GT4 confirmed for the full season calendar battling for outright GT4 championship honors, with entries in the Silver and ProAm classes.

Leading the GT4 charge will be Tolman Motorsport as the team returns for the season with a two-car entry wearing striking new liveries. The 2019 GT4 championship runners-up will once again line up with the newly selected McLaren Automotive Driver Development Programme (DDP) drivers. Now entering its third season, the DDP continues to nurture young motorsport talent, and this year has expanded the reach of the program beyond the UK with international drivers representing Australia, North America, and Switzerland. It has now been confirmed that Michael Benyahia and Alain Valente will be paired up in the number #4 570S GT4, while Harry Hayek will race alongside Katie Milner in the number #5.

After confirming a move to join McLaren Customer Racing earlier this year which will see Optimum Motorsport run the 720S GT3 in both the GT World Challenge Europe powered by AWS and Intelligent Money British GT Championship, the team will also contest the domestic championship’s GT4 class with Pure McLaren GT Series graduates Brendan Iribe and Nick Moss partnering with professionals Ollie Millroy and James Pickford in two ProAm entries. The four drivers have previously raced together, clinching victory at the Gulf 12 Hours at the close of the 2019 season.

In parallel to a two-car entry in the GT4 European Series, HHC Motorsport returns to the British GT Championship running with a pair of 570S GT4s for a second season. After winning the opening round of 2019, the team will be looking to make another immediate impact on the championship with a double Silver class entry. Gus Bowers and Chris Wesemael both make a step up to GT4 competition and debut in the series. The driver line-up for the second car will be confirmed in due course.

Completing the line-up of McLaren Customer Racing GT4 entries is Balfe Motorsport, bringing the total number of entries for the McLaren brand on the grid to a record 12. McLaren Professional Driver Michael O’Brien partners with Graham Johnson for a second season, while the first racing commitment since his appointed as Factory Driver will see Euan Hankey racing alongside double-Pure McLaren GT Series champion Mia Flewitt who makes a return to the British GT championship for her first full season.

“British GT’s official Safety Car partnership with McLaren Automotive enters its fifth season this year, extending one of the championship’s longest-running associations. We’re delighted to have the 720S - likely to be the world’s most capable Safety Car - leading our supercar pack to the start of every round once again, while the manufacturer’s GT3 and GT4 models make up one-third of this year’s full-season entry. We’re very proud that such an iconic British brand continues to have a high-profile presence in one of the UK’s biggest motorsport series.”Lauren Granville, Intelligent Money British GT Championship Manager

Intelligent Money British GT Championship 2020 – confirmed entries for McLaren Customer Racing teams:

720S GT3 : GT3 championship – ProAm

Balfe Motorsport:

#22 – Shaun Balfe (GBR), Rob Bell (GBR)

Optimum Motorsport:

#68 – Martin Berry (AUS), Nick Foster (AUS)

720S GT3 : GT3 championship – Silver

2 Seas:

#09 – Isa Al-Khalifa (BAH), TBC

#10 – Angus Fender (GBR), Dean MacDonald (GBR)

570S GT4 : GT4 championship – ProAm

Balfe Motorsport:

#20 – Graham Johnson (GBR), Michael O’Brien (GBR)

#21 – Mia Flewitt (SWE), Euan Hankey (GBR)

Optimum Motorsport:

#27 – Nick Moss (GBR), James Pickford (GBR)

#88 – Brendan Iribe (USA), Ollie Millroy (GBR)

570S GT4 : GT4 championship – Silver

Tolman Motorsport:

#4 – Michael Benyahia (USA), Alain Valente (SUI)

#5 – Harry Hayek (AUS), Katie Milner (GBR)

HHC Motorsport:

#57 – Gus Bowers (GBR), Chris Wesemael (GBR)

#58 – TBC, TBC

Photo credit: Brian Williams, SpiedBilde

Spy Shots—Refreshed Mustang Bullitt or Mach-1 Prototype?

Aston Martin V12 Speedster

A Puristic Limited Edition for the most demanding drivers.

Limited-edition V12 Speedster unveiled at Aston Martin’s Gaydon headquarters

Open, uncompromising, visceral, two-seater layout with only 88 examples

‘Q by Aston Martin’ F/A-18 livery showcases conceptual specification pack

Pricing starts from £765,000. Now available to order. Deliveries Q1 2021

Wednesday 4 March, Gaydon: The Aston Martin V12 Speedster has made its global debut today, with just 88 examples of this puristic limited-edition model set to hit the road.

Created by luxury British marque’s bespoke customization service ‘Q by Aston Martin’, the Aston Martin V12 Speedster is a truly visceral driver’s car that draws inspiration from both the brand’s rich racing history and aeronautical design. Today’s example is showcased in a conceptual F/A-18 livery, also curated by the same artisans.

Aston Martin Lagonda President and Group CEO, Dr. Andy Palmer

Aston Martin Lagonda President and Group CEO, Dr. Andy Palmer said: “It makes me enormously proud to reveal Aston Martin’s latest, most exciting special model today. The V12 Speedster is an incredible demonstration of the breadth of capability and determination from the ‘Q by Aston Martin’ team, who have worked tirelessly to create this stunning, two-seat sports car aimed at our most demanding and enthusiastic customers.”

Conceived a little over 12 months ago, the V12 Speedster has undergone an intensive development program, going from drawing board to production reality within that short period. Demonstrating the skills and meticulous planning of ‘Q by Aston Martin’ and Aston Martin Design, the V12 Speedster is a living show car, underlining the company’s commitment to delivering customers a stunning driver’s car, using the engineering ingenuity and advanced materials evident throughout the entire Aston Martin range.

Utilizing Aston Martin’s latest bonded aluminum architecture, the V12 Speedster utilizes elements from both the DBS Superleggera and Vantage model lines to create its own unique platform. With independent double-wishbone front, and multi-link rear suspension with coil springs and adaptive damping offering Sport, Sport+ and Track modes, the V12 Speedster also benefits from standard 21-inch forged center-lock alloy wheels. Carbon Ceramic Brakes of 410mm on the front axle and 360mm at the rear are also standard equipment.

Miles Nurnberger, Director of Design, Aston Martin Lagonda

Over the V12 Speedster’s unique chassis is a bespoke body constructed almost entirely from carbon fiber. Miles Nurnberger, Director of Design, Aston Martin Lagonda, said: “With the V12 Speedster we do go back a step and look into our past for inspiration. Since the DB11 launch, everything has been focused and very forward-looking. Here though, we find a different tempo. There’s the clear lineage from the 1959 Le Mans-winning DBR1 to our Centenary celebratory CC100 Speedster Concept in 2013. There is also a bit of 1953 DB3S in the mid-section, so it really is our latest incarnation of the Speedster concept. It’s also inspired by fighter jets as much as it is by our history, and it has been created to deliver an incredibly visceral experience, hence why it is a V12, rather than a V8. With the V12 Speedster, we are amplifying all the emotional strings that we can to the absolute maximum.”

Nurnberger adds: “No roof or screen, a big engine, low, with broad shoulders and exaggerated and emotional styling with twin humps and the spine separating the driver and passenger. The light, low, rear-end contrasts with the bold, enlarged grille, unique headlights, and bonnet nostrils at the front. The bonnet nostril we haven’t done in a very long time, but we’ve brought them back. It’s a neat trick visually to allow us to win some space for the V12. It creates this iconic looking vent.”

The interior specification pushes new boundaries, using a mix of traditional and modern materials. Structural satin carbon fiber contrasts with traditional hand-crafted Saddle Leather, chrome, aluminum and even 3D printed rubber. Visually and physically the interior reduces mass, for a leaner, efficient style, but one that retains all the emotion and craftsmanship Aston Martins are renowned for. In front of the passenger is a removable leather bag in place of a traditional glove box, while there’s additional storage space under the rear bumps for luggage.

Unveiled here today at Aston Martin’s Gaydon HQ, the V12 Speedster has been shown in a conceptual specification that is inspired by the legendary F/A-18 and will be available for customers to order. Born from an exciting new collaboration with Boeing and created by the brand’s bespoke customization service ‘Q by Aston Martin’, this striking livery takes the legendary fighter jet for inspiration and is finished in Skyfall Silver, with contrasting satin black on the exhaust tips, vent grilles, and vanes. The dark theme is carried through to the interior, with satin dark chrome, machined aluminum, black leather, black technical textile, black carpets, and vivid red Aston Martin scripted door pulls, creating a purposeful look for this conceptual styling.

Powering the V12 Speedster is Aston Martin’s scintillating 5.2-liter, Twin-Turbo V12 engine, with a peak output of 700hp1 and 753Nm1 of torque. Front mid-mounted, the all-alloy, quad-cam 48-valve engine is mated to a ZF 8-Speed automatic transmission with a limited-slip differential driving the rear wheels. The V12 Speedster is able to accelerate to 62mph (100km/h) in 3.5 seconds on the way to limited top speed of 186mph (300km/h)1.

The iconic V12 engine promises scintillating performance, but further underlining the V12 Speedster’s abundant character and unparalleled commitment to a thrilling drive is an even more invigorating aural signature. To create this Aston Martin’s engineers have created a bespoke stainless-steel exhaust system exiting centrally into the diffuser surface at the rear of the car for an even more rousing, characterful sound from the drivetrain. With the V12 Speedster, every element of the drive is experiential, most obviously the removal of the windscreen adding to the visceral engagement, heightening the driving experience to new levels.

Matt Becker, Aston Martin Chief Engineer, said: “for raw, driving thrills the V12 Speedster is unparalleled, the fully open element of the car adding a new dimension to the experience. It engages on every level, delivering a precise, involving driving experience, with agility and poise backed by abundant power from Aston Martin’s twin-turbo 5.2-litre V12. Driving doesn’t get any purer than this.

Aston Martin Lagonda President and Group CEO, Dr. Andy Palmer said: “nothing demonstrates Aston Martin’s commitment to providing unique, special models to its customers more than the V12 Speedster. The 88 hand-built cars will be sought after by driving enthusiasts and collectors alike all around the world. I’m excited not just about what they offer drivers, but of what it represents. The V12 Speedster not just showcases our incredible engineering capability and ambition, but also celebrating Aston Martin’s rich heritage.”

Orders are now being taken for the V12 Speedster, with pricing starting at £765,000 including VAT and deliveries expected to begin in the first quarter of 2021.

1Estimate

Shop Spotlight: Z Car Garage

Class action could mean refund of £60 per new car

Class action could mean refund of £60 per new car https://t.co/wpHHAjox7E pic.twitter.com/UH3ztBMp35

— Car Dealer Mag (@CarDealerMag) March 3, 2020

Hispano Suiza Carmen Boulogne

A sports-focused, tailormade evolution of the Carmen that reflects the brand's racing heritage

The motorsport-inspired Carmen Boulogne pays homage to Hispano Suiza's competition heritage

The Carmen Boulogne boasts 820kW (1,114PS), a 290km/h (180mph) top speed and a 0-100km/h time of under 2.6 seconds

Fully carbon fiber sub-chassis achieves a weight of just 1,630kg. Optimized suspension and carbon fiber enhancements save 60kg vs Carmen

The infinitely-customizable Carmen Boulogne embodies the sporting spirit of Hispano Suiza alongside a strong family legacy

Barcelona, 3 March 2019 – The motorsport-inspired Carmen Boulogne pays homage to Hispano Suiza's competition heritage. Building on its sibling’s substantial credentials, the Carmen Boulogne boasts 820kW (1,114PS) up by 70kW (95PS); more speed 290km/h (180mph) up by 40km/h (25mph) and a 0-100km/h time of under 2.6 seconds.

Utilizing Carmen's expertly engineered chassis and powertrain technology, Carmen Boulogne delivers a blend of exhilarating power, exceptional luxury, and elegant design.

Born of the brand's 'Unique Tailormade' department in Barcelona, the infinitely-customizable Carmen Boulogne embodies the sporting spirit of Hispano Suiza alongside a strong family legacy.

The new sportier variant of the Carmen is the next stage in the evolution of the resurgent Spanish luxury car brand. Designed, developed and manufactured in Barcelona, the fully-electric Carmen Boulogne shares its sibling’s classically-inspired design, but applies sportier styling and showcases the extent of customization available to the five customers who will own one of the hyper-exclusive models.

Combining its enhanced, fully-electric 820kW (1,114PS) powertrain with a bespoke super-stiff carbon fiber monocoque, stiffer double-wishbone front, and rear suspension, and torque vectoring, the Carmen Boulogne delivers exceptional dynamics, with a focus on thrilling performance. With such prodigious power, and a curb weight of 1,630kg, the new variant has world-class performance capabilities: 100km/h is reached in under 2.6 seconds, while the top speed is 290km/h.

The car’s exquisitely-precise carbon fiber bodywork is proudly displayed beneath a clear coat varnish, which emphasizes its aggressive sportiness while retaining Carmen’s timeless elegance. Inside, the Carmen Boulogne variant is distinguished from its sibling through the use of suede or black Alcantara across the bulkhead and door panels.

The car’s design, engineering, and production has been undertaken in Barcelona by a skilled team of highly-experienced experts from Hispano Suiza and QEV Technologies – a company that specializes in electric powertrain development and motorsport engineering.

The Hispano Suiza Carmen Boulogne will cost from €1.65m (plus taxes). The five special edition Boulogne variants join 14 Carmen or Carmen customized models to complete the total 19-unit production run, with the first customer taking delivery in 2022. Prospective customers can now register their interest to purchase one of the hyper-exclusive models.

A product of the brand’s ‘Unique Tailormade’ operation, the Boulogne features design enhancements that reference Hispano Suiza’s racing vehicles from the 1920s, while building on Carmen’s exhilarating performance and exceptional luxury.

The Boulogne moniker dates back to 1921 and the George Boillot Cup, in which Hispano Suiza competed with a performance-focused version of the company’s H6 Coupé. The endurance race saw competitors battle for victory for more than 3.5 hours, on the roads around the French town of Boulogne.

Hispano Suiza achieved three consecutive race wins, with drivers André Dubonnet (1921), Paul Bablot (1922) and Léonce Garnier (1923) driving specially-modified versions of the Hispano Suiza H6.

Purposeful sports styling builds on Carmen’s contemporary reimagination of a classic shape Hispano Suiza

Carmen’s styling is deliberately provocative, intended to generate an emotive reaction and to be instantly recognizable. The Carmen Boulogne extends this theme, adding a layer of menacing mystique through its exposed carbon fiber – deeply polished beneath a lustrous clear coat.

Emphasizing its enhanced performance capabilities, the new model features copper-colored livery that highlights the car’s aerodynamic form. It makes use of the original model’s large air inlets that flank the grille, sitting above a ‘floating’ front splitter, which channels air under the car.

The Carmen Boulogne carries the same semi-circular combination headlamps and aggressive ‘frown’ as its sibling but is clearly differentiated by its dominating copper-colored grille.

Visual theatre is a key element of the Hispano Suiza DNA. Before even entering the car, the driver and passenger are provided with a dramatic performance as the scissor doors rise and pivot in one smooth, elegant movement. With the doors closed, Carmen’s distinctive aerodynamic teardrop profile is revealed. Here, a key styling element that differentiates the Boulogne variant appears where the concave bodyside scoop ends, just as the dramatic rear haunch takes over – the rear wheel is exposed rather than being shrouded.

This unobscured view of the 20-inch rear wheels serves to emphasize the new model’s sports focus while also enhancing cooling of the carbon-ceramic brakes (discs: AP Racing 380mm x 34mm; calipers: AP Racing Radi-CAL - 6 pistons). Newly-styled wheels are proudly displayed with 10 curved trapezoidal shapes set around the outer rim and a series of concentric circles framing the central Hispano Suiza emblem. With front and rear wheels on show, the Carmen Boulogne is visually more balanced than its Grand Tourer sibling, and benefits from a more menacing stance – a characteristic emphasized by its black carbon fiber bodywork.

Viewed from the rear, the taught haunches that arch over the covered rear wheels also feature copper-colored detailing. They taper slightly, flanking a dramatic narrowing of the roofline and rear screen that ends in a distinctive, sharp, rear-facing point – the trailing tail of the teardrop.

The circular rear combination lamps feature the signature Hispano Suiza stork graphic within the rear-light cluster. When seen from an angle, the indicator pulses along the length of the rear-lamp cones creating an arresting visual spectacle.

The performance focus of the Carmen Boulogne capitalizes on the car’s low drag coefficient (Cd 0.325), lower than the Porsche 918 Spyder (0.34), Koenigsegg Agera R (0.37) and Ferrari F12 (0.33). In accelerating to its top speed of 290km/h, it makes full use of its streamlined form, combined with the front splitter, flat floor and rear diffuser that work in unison to reduce lift.

Exquisite and luxurious interior blends modern technologies with contemporary design cues

The passenger cabin of the Carmen Boulogne is a more contemporary take on Hispano Suiza’s blend of premium quality materials and classic design cues. The Carmen’s refined and luxurious wood trim is replaced by suede or black Alcantara, while chrome trim is changed for anodised metal in a striking Orange Tulipwood colour.

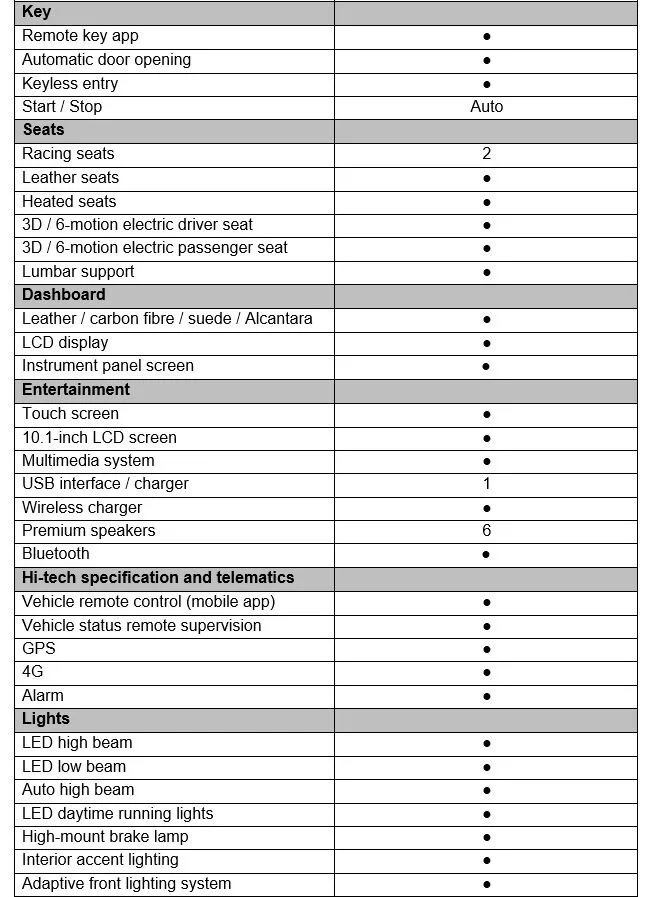

Awaiting the occupants inside the car is a combination of the finest leather and Alcantara that is used to trim the heated, 3D / 6 motion power-adjustable carbon fibre composite seats, as well as the door panels and roof lining. All upholstery is hand-trimmed and hand-sewn in-house at Hispano Suiza’s Barcelona assembly facility, helping ensure that the driver and passenger are cosseted within an authentically sumptuous environment.

Such is the focus on the ultimate ownership experience, each Carmen Boulogne is almost infinitely customisable via the brand’s ‘Unique Tailormade’ department. Buyers can pick the specific shade of leather, the set-up of the interior mood lighting, and can even specify a custom-perfumed interior, developed with the buyer to ensure the car is aligned perfectly with their preferences.

The artisan craftsmanship that is apparent throughout the interior retains a direct lineage to the brand’s history. For example, the dash reflects the characteristics of the Carmen Boulogne’s predecessors, with anodised Orange Tulipwood-coloured metalwork perforated by authentic toggle switchgear for reassuring mechanical tactility. The clockface at the centre of the dash features a Swiss mechanism with design and development by a Spanish watch maker. It echoes the position and status of the timepieces that featured in the brand’s earlier cars. Similarly, the triangular gear selector is a direct reference to the art deco steel triangle that featured on the dash of Hispano Suiza’s in the company’s historic models.

While the style is unashamedly retrospective, the technologies employed deliver the best experience possible for occupants. Ambient LED lighting strips are hidden along the door panels and in the footwells to ensure that the interior is a welcoming and inviting space.

The steering wheel spokes feature smartphone and multimedia controls, while a highly-intuitive user interface sits at the centre of the driver-focused infotainment console. A high-definition, 10.1-inch touchscreen display allows owners make infotainment selections and configure vehicle settings with ease. The screen is also where video output from the rear parking camera is presented. High-fidelity audio is delivered by six premium speakers and a subwoofer, providing a unique 360-degree audio experience.

A dedicated Hispano Suiza mobile app enables owners to remotely set cabin temperature, operate the lights, and set the alarm, as well as monitoring the battery charge status.

Advanced electric powertrain delivers motorsport-inspired performance

Achieving enhanced performance, to elevate the Carmen Boulogne to even greater heights, was the primary focus for the Hispano Suiza technical team. Inspired by the brand’s race-winning successes of the 1920s, the engineers set out to boost the Carmen’s exceptional power even further.

Building on the Carmen’s substantial credentials, the Carmen Boulogne boasts 820kW (1,114PS) up by 70kW (95PS) on its sibling. With a longer-ratio gearbox, a new silicon carbide transistor, and stiffer suspension, the performance variant has a higher top speed 290km/h (180mph) up by 40km/h (25mph), and boasts a 0-100km/h time of under 2.6 seconds.

The Carmen Boulogne is powered by two 410kW permanent-magnet synchronous motors (PMSM), one for each rear wheel. Each motor’s significant torque is controlled through sophisticated torque vectoring systems developed in-house. From 0-6,500rpm, the motors are capable of 1,600Nm maximum torque, enabling the car’s blistering acceleration and seemingly endless pulling power.

The high-energy battery pack is T-shaped, running as a central spine of the car and behind the seats. It also serves as a tuned mass damper (TMD), providing stability and reducing structural vibration.

The Lithium Ion polymer battery pack boasts an available capacity of 80kWh. High-efficiency mechanical and electric components give a total energy loss from the battery to the ground of less than 10%, maximising vehicle range, which is targeted to exceed 400km.

The battery pack – made up of 700 cells – was designed and produced entirely in-house, including a complete temperature control system to ensure the cells can operate optimally. The battery monitoring system ensures stable charge and discharge performance and delivers the required safety strategies.

The new model also features >80kW DC Fast Charging capability, requiring just 30 minutes to charge from 30-80% via a CCS2 Fast Charger. It also features CHAdeMO and GB/T charging options.

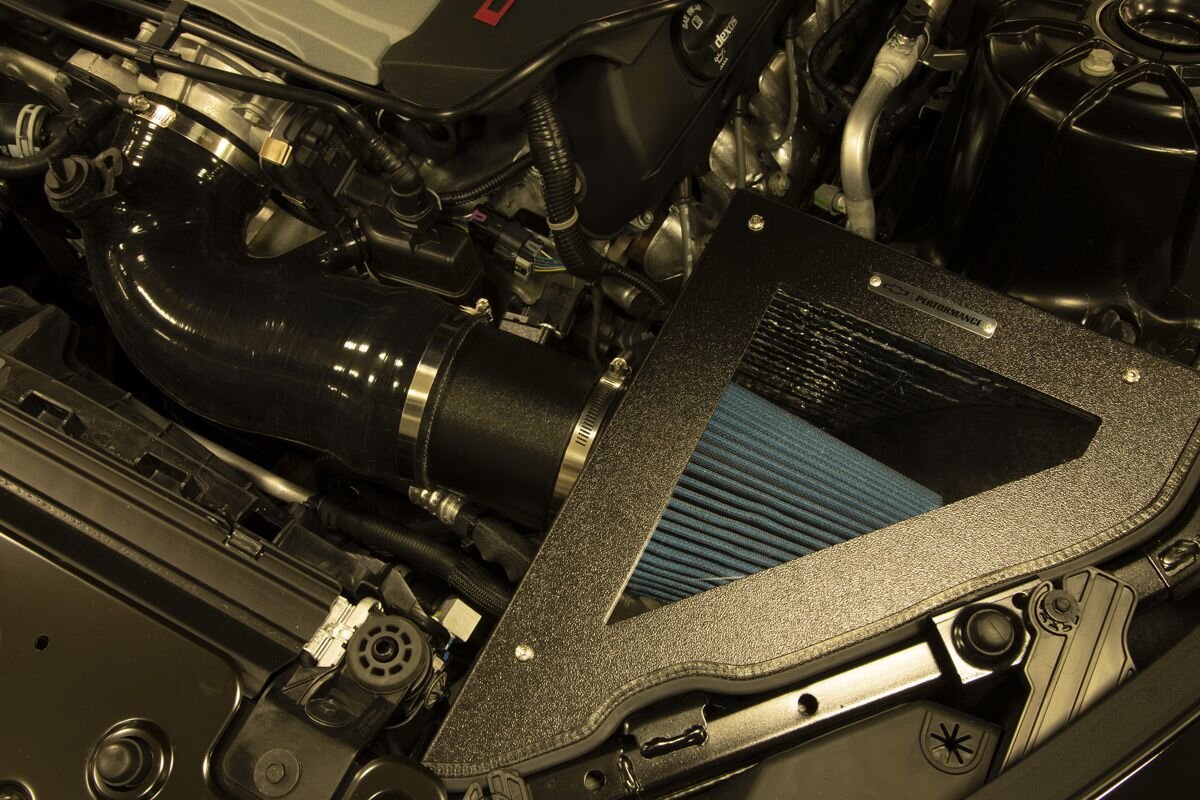

The battery and electric powertrain components are liquid-cooled via three front radiators: one under the hood at the front of the car for battery cooling, and one each side, inboard of the front wheel arches, for cooling powertrain components. The three front air intakes provide airflow to help cool the electric drivetrain system and battery. The location, size and diffuser-style shape of these intakes, together with split planes, distribute the air in the radiator’s core to achieve the optimal balance of drag and high air flow across the radiators. The outlets in the hood that expel air from the front radiator, and those in the front wheel arches that expel air from the side radiators, have been carefully designed and located to minimise drag.

Battery heat expulsion is controlled by the front central radiator and condenser. The battery thermal management system uses a passive heat exchanger (radiator) and an active cooling system, which shares its refrigeration cycle with the passenger cabin’s air conditioning. Also, a PTC (Positive Temperature Coefficient) heater warms the battery in cold conditions.

The car’s Electronic Control Unit (ECU) software manages all vehicle power and control strategies, continuously interrogating myriad data streams and instruction actuators to control vehicle behaviour. These strategies are all developed and tested in-house by Hispano Suiza software engineers. A complex network feeds a huge amount of data to the ECU at a rate of up to 1,000 samples per second.

Data is also fed via the cloud to the Hispano Suiza back office infrastructure to ensure that vehicle status and condition is monitored by Hispano Suiza in real time to ensure ultimate reliability. This 4G functionality also enables eCall emergency services as required.

Hispano Suiza’s production partner – QEV Technologies – has extensive experience in developing electric vehicle powertrain technology, specifically for teams participating in FIA Formula E and FIA Electric Production Car Series (EPCS). As such, QEV Technologies brings unprecedented levels of engineering know-how to the Carmen Boulogne’s electric powertrain, contributing to its exceptional performance, efficiency, reliability and safety.

Bespoke carbon fibre monocoque chassis

The Hispano Suiza Carmen is one of the most carbon fibre intense cars in the world. Carbon fibre composites are employed extensively throughout the vehicle, and account for the vast proportion of vehicle structures.

Even in this, the most elementary structure of the Carmen, Hispano Suiza has created a unique work of art: the hand-laid carbon fibre deployed for the monocoque chassis is specifically oriented in a mirrored opposing weave pattern. This results in a forward-facing directional arrow shape down the centre-line of the car from back to front. Uniquely, in the Carmen Boulogne, this detailed and beautiful carbon fibre craftmanship is proudly displayed beneath the car’s clearcoat varnish.

Carbon fibre composite is also used for the crash protection structures that absorb and dissipate impact energy to protect the monocoque at the front and rear. Unusually, the rear subframe is also constructed in carbon fibre and is bolted to the primary chassis structure.

The monocoque chassis weighs only 195kg and exhibits exceptionally high rigidity to provide a torsional stiffness rating of 50,000Nm/deg. This not only contributes to a stronger and safer passenger cell, but also benefits the car’s dynamic performance. The Carmen’s stiffness-to-mass ratio (256Nm/deg per kg) out-performs any other hypercar: for comparison, the Lamborghini Aventador’s stiffness-to-mass ratio is 237Nm/deg per kg.

Through extensive development of the Carmen during the past year, the Boulogne boasts a weight of just 1,630kg, a saving of 60kg versus its sibling. The enhancements have been achieved through a newly optimised suspension (-25kg); a new sub-chassis (-15kg); chassis lay-up optimisation (-15kg); new CNC parts and carbon fibre roof (-6kg). The 11 carbon fibre body panels are also incredibly lightweight, tipping the scales at just 64.5kg – including the front splitter and rear diffuser.

Even the seat structures and interior upholstery-support panels are carbon fibre composites. Furthermore, composites are also deployed as electric insulation materials and as part of the car’s NVH management, as a sound and vibration dampening substance.

Inspired by the brand’s performance-focused past, the Carmen Boulogne’s blistering straight-line speed is married with driver-focused dynamic capabilities thanks to the highly experienced team. It has developed and integrated a range of advanced chassis systems to achieve the dynamic goals for the car. Not only will the Carmen Boulogne exhibit exceptional handling, but the characteristics and behaviour of the car should be predictable and easy to drive. Carmen Boulogne is a racing-inspired car for the road that embraces and harnesses the most advanced motorsport-inspired technologies and techniques to engage and bring joy to the driver.

Double wishbone suspension is fitted at the front and rear, which is paired with adaptive damping control and variable roll stiffness distribution technologies to deliver precise and responsive handling, while retaining a refined and comfortable ride. Notably, the suspension set-up of the Carmen Boulogne has been stiffened slightly to account for the car’s sportier nature.

True torque vectoring manages the distribution of the two motors’ torque to each rear wheel, according to driver inputs and levels of grip available. This provides a series of benefits, particularly in dynamic response during the most spirited driving, greater high-speed stability, and improved safety on low-grip surfaces.

Additional active safety technologies include anti-lock braking (ABS), traction control (TCS) and electronic stability control (ESP) systems. Meanwhile, the Carmen’s brakes are powerful carbon-ceramic composite units from AP Racing. The 380x34mm front and rear ceramic discs work with the six-piston Radi-CAL calipers to ensure the Carmen Boulogne can shed speed rapidly and consistently.

A proud Spanish spirit and strong family legacy

Hispano Suiza was responsible for the design and manufacture of more than 12,000 luxury performance cars and 50,000 aeroplane engines between 1904 and 1946. Even before he joined Hispano Suiza as its Technical Director, Marc Birkigt experimented with cutting edge technologies in the new era of the automobile, leading a team that built one of Spain’s first electric car prototypes in 1899.

Some of the innovations that he later went on to develop helped Hispano Suiza cars to be considered among the world’s finest and most advanced. Indeed, many media and high-profile automotive enthusiasts considered the brand’s cars among the best in the world. Even three decades after Hispano Suiza stopped making cars, other luxury brands were still using automotive technology licenced from Hispano Suiza.

Hispano Suiza is a fourth-generation family business. Its president, Miguel Suqué Mateu is the great-grandson of the brand’s founder, Damián Mateu. It is believed that Hispano Suiza is unique in nurturing an unbroken family lineage in the reintroduction of an automotive brand born in the first era of the automobile. The company is intensely proud of its Spanish roots – its headquarters, technical centre, and manufacturing facility are all based in Barcelona, and more than three-quarters of the Carmen’s components are sourced in Spain.

Through the President, the Mateu family retains an intimate relationship with the reborn Hispano Suiza operation, influencing the brand’s direction, management, and planning, plus the design and specification of the new Carmen Boulogne.

Grup Peralada

Grup Peralada was established in 1904 and has been owned and managed by the Suqué Mateu family since it was founded. The group of businesses has continued to grow and represents the pinnacle of luxury in gastronomy and entertainment. Its highlights include a three-time Michelin star restaurant – Castell Peralada – in north-east Spain, where it also owns 12 award-winning wineries, an 18-hole golf course and hotel and offers the world’s first wine-spa health treatments. It also hosts the annual Peralada International Music Festival, celebrating the arts, opera and ballet. It operates 21 restaurants, eight casinos and six five-star hotels across Europe and Latin America.

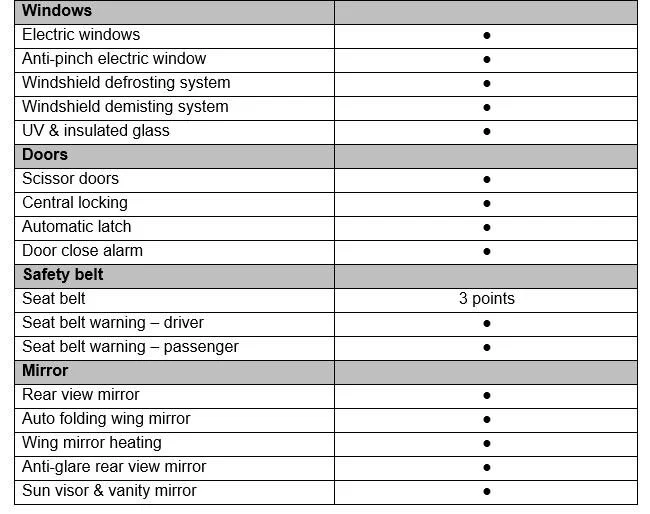

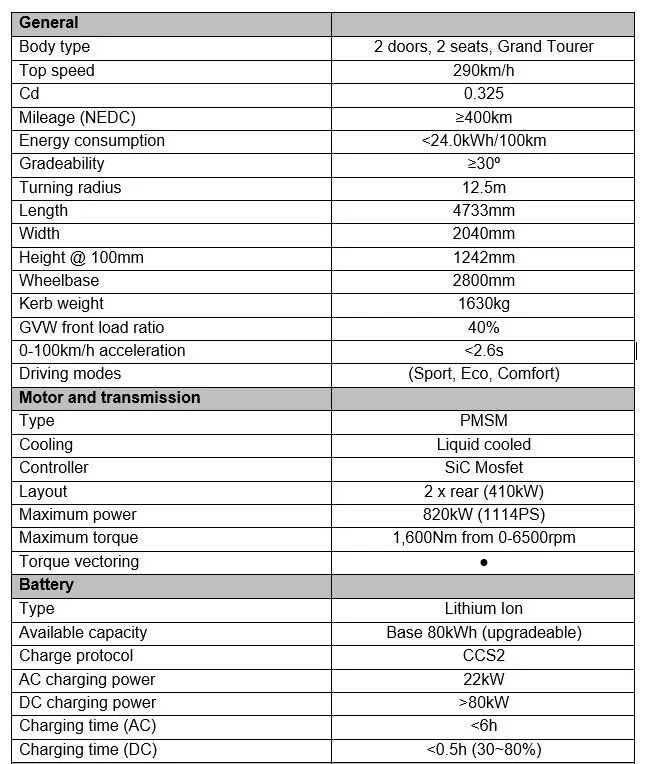

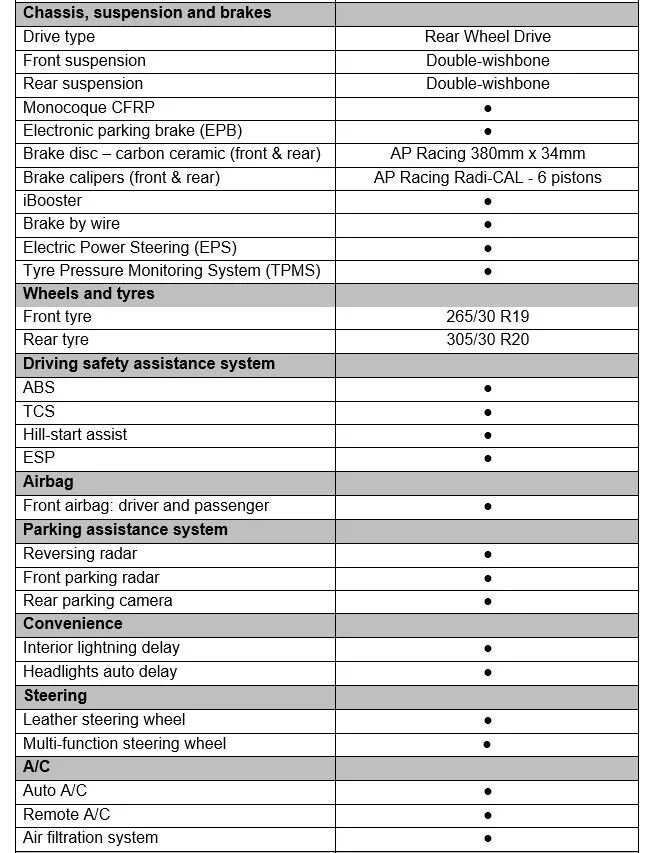

Technical specification: Hispano Suiza Carmen Boulogne

Social media

Facebook: HispanoSuizaCars

Twitter: HispanoSuizaCar

Instagram: HispanoSuizaCarsOfficial

YouTube: Hispano Suiza

Fiat Debuts All-new 500 in Milan

March 4, 2020 , Auburn Hills, Mich. - Today in Milan, Italy, FCA presented the all-new Fiat 500, featuring a 42-kWh lithium-ion battery and an 85-kW fast charger. With an output of 87 kW, the new 500 delivers acceleration from 0-62 mph in 9.0 seconds and 0-31 mph in only 3.1 seconds. The new 500 offers level 2 autonomous driving that includes intelligent Adaptive Cruise Control (iACC) and Lane Centering. Measuring 2.4 inches wider and 2.4 inches longer, with a wheelbase extended by 0.8 inch, the new 500 is the first Fiat car equipped with the new Uconnect 5 infotainment system, offering a 10.25-inch high-definition touchscreen. The new Fiat 500 has not been confirmed for the U.S. FCA is evaluating its potential for the North American market.